Hot-selling Plaster Powder Production Line - Powder coating spray painting hot air circulation drying oven – FOD Electrical Eng

Hot-selling Plaster Powder Production Line - Powder coating spray painting hot air circulation drying oven – FOD Electrical Eng Detail:

- Condition:

- New

- Type:

- Coating Production Line

- Substrate:

- Aluminum

- Coating:

- Powder Coating

- Place of Origin:

- Chongqing, China (Mainland)

- Brand Name:

- FOD

- Voltage:

- 380~440V

- Power(W):

- Multi Power

- Dimension(L*W*H):

- Customized Size

- Weight:

- 4 TONS

- Certification:

- CE ISO9001

- Warranty:

- 12 Months

- After-sales Service Provided:

- Engineers available to service machinery overseas

Packaging & Delivery

- Packaging Details

- Film and Wooden case

- Delivery Time

- 25 Days

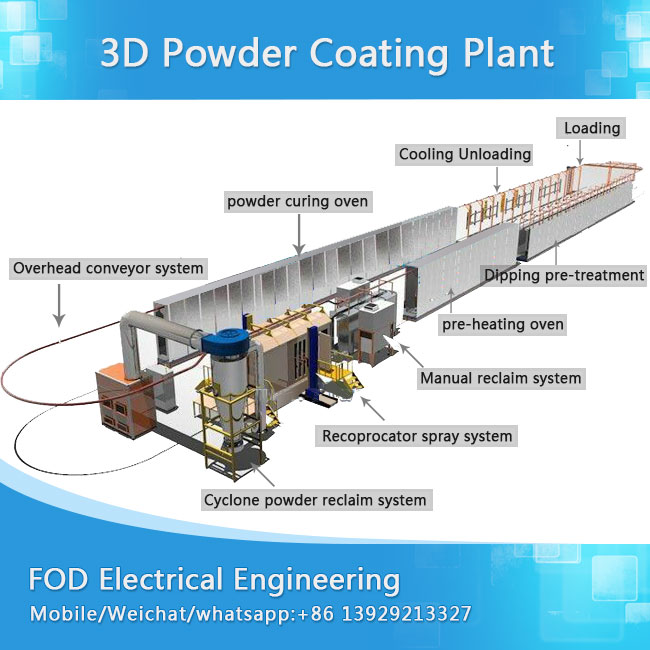

1.Powder coating spray painting hot air circulation drying oven Brief

Our ovens are main designed on hot air circulation concept. The inside oven temperature can be achieved room temperature to 250 degree. The heated hot air and around the product to maximize the powder drying efficiency.

The heating center system gas Safety Purge Time requirements are met using the unique system. Generally, the oven can purge as per regulations in around 3 minute instead of the normal 15 minutes.

2.Powder coating spray painting hot air circulation drying oven Process and Parameter

Dring oven parameter

|

1,Oven type |

Hot air circulation drying oven |

|

2,Heating type |

Burner with gas tank |

| 3,Drying temperature |

100-350 degree |

|

4,Main material |

Steel frame and Mirror stainless steel inner wall |

| 5, Insulation |

4 sides100mm thickness rock wool insulation wall |

|

6,Temperature indicator |

OMRON temperature card |

|

7,Control system |

PLC touch screen |

|

12,Widely Application |

Automobile accessories, motor bike part, bicycle part, air conditional, steel pipe and other hardware metal powder coating |

2.Powder coating spray painting hot air circulation drying oven Picture Show

5.Our Maintenance Guarantee

One year warranty will be provided on the condition of normal operation of the machine. During the period of warranty, damaged parts could be exchanged at free if the damaged is owing to bad quality of the goods, Damaged parts is required to return us. If it was damaged by human being, parts will be exchanged or repaired at cost as quotation.

Engineer is available to have installation,trainning serive for oversea customer.

6.Fast Shipping Delivery

1.Deliery within 10working days.

2.FOB Shenzhen or CIF sea shipping.

3.Wooden case package avoiding damage

7.Contact us for the latest Price of Manual Powder Coating Plant

Product detail pictures:

Related Product Guide:

Using Conveyor Systems

Guidelines For Choosing a Conveyor System

Our pursuit and company goal is to "Always satisfy our customer requirements". We continue to develop and design superior quality products for both our old and new customers and achieve a win-win prospect for our clients as well as us for Hot-selling Plaster Powder Production Line - Powder coating spray painting hot air circulation drying oven – FOD Electrical Eng , The product will supply to all over the world, such as: Rome, Indonesia, Cologne, Since our establishment, we keep on improving our products and customer service. We are able to provide you with a wide range of high quality hair products at competitive prices. Also we can produce different hair products according to your samples. We insist on high quality and reasonable price. Except this, we provide best OEM service. We warmly welcome OEM orders and customers all over the world to cooperate with us for mutual development in the future.

The manufacturer gave us a big discount under the premise of ensuring the quality of products, thank you very much, we will select this company again.