Conveyorize spray painting production line for wine bottle

- Place of Origin:

- Chongqing, China (Mainland)

- Brand Name:

- FOD

- Model Number:

- FAL-gf01

- Condition:

- New

- After-sales Service Provided:

- Engineers available to service machinery overseas

- Application:

- lacquer painting

- Spraying type:

- FIX Gun+spindle jig rotation

- Function:

- Full Automatic spray painting tratment

- Warranty:

- 12 Months

- Voltage:

- 220v/380v/440v/50HZ/60HZ

Packaging & Delivery

- Packaging Details

- Film and Wooden box

- Delivery Time

- 30 days

1.Full Automatic spray painting production line for wine bottle Brief

We specialized in manufacturing one-step automatic spray painting solutions for 12 years. Supplying scope covering UV liquid Fix gun spray painting plant ,Five axis reciprocating spray painting plant, X-Y reciprocating painting line and Robotic spray painting line. The Gun fix spray painting line works flexible as different product shape with spindle self-rotation system. It is widely used in various industries, like toys, plastic shell, cosmetic cup cap, automotive spares automatic spray painting.

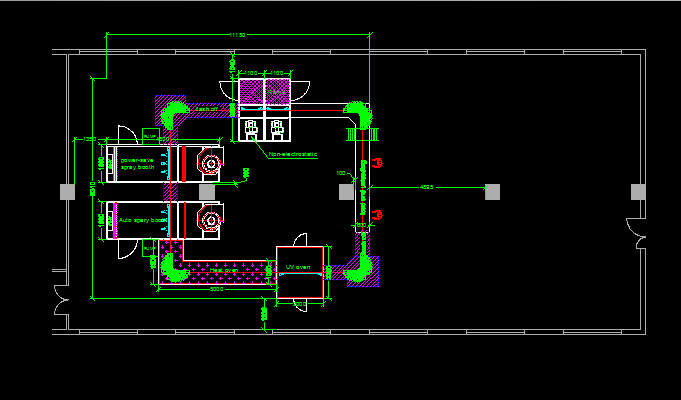

2.Automatic painting Line Full Process:

Loading—Antistatic dust-free–Base coat—Flash off—-Top coat—Drying—Curing–Cooling—Unloading

Project Example

3.Fix Gun spray painting line Main Systems

1)Electrostatic& Flame pre-treatment booth :

2)Spray booth with spindle rotation system

3)Automatic Spray gun system

4)IR drying oven

5)UV curing oven

6)Chain Conveyor system

7) Air supplying unit

8) Paint mixing& supply system

9)PLC touch screen control system

|

1,In put |

110V/220V/380/415V/440V,50HZ |

|

2,Output Power |

54KW (as per final design) |

|

3, Electrostatic booth |

L1100mmX W1500mmXH2000mm |

|

4.Spray booth |

L2250mmX W2000mmXH2000mm |

|

4,No. Spray Gun |

1-4 PCS Devilbiss/ Graco spray gun |

|

5, Spay coating type |

Fix gun +Spindle jig self rotation |

|

6, Oven temperature |

80℃ adjustable+ Rock wool insulation |

|

7.Paint mixing system |

Graco paint mixing pump |

|

8, Conveyor Speed |

0-6m/min adjustable |

|

9,Control Panel |

PLC touch screen |

|

10,Main Material |

Stainless steel &steel |

|

11,Widely Application |

Toys, Helmet, bottle,Laptop, display, LCD TV,Cellphone,MP3,Button,Desk computer Keyboard, Portable hard drive, Plastic ball, Car spare parts, Photo Frame, |

4.Fix Gun spray painting line Main Systems Picture Show

3.1 Spray gun system

3.2

3.2 Drying oven

3.4 Paint Mixing & Supply system

3.4 Unloading area

5.Maintenance Guarantee

One year warranty will be provided on the condition of normal operation of the machine. During the period of warranty, damaged parts could be exchanged at free if the damaged is owing to bad quality of the goods, Damaged parts is required to return us. If it was damaged by human being, parts will be exchanged or repaired at cost as quotation.

Engineer is available to have installation,trainning serive for oversea customer.

6.Fast Shipping Delivery

1.Deliery within 10working days.

2.FOB Shenzhen or CIF sea shipping.

3.Wooden case package avoiding damage